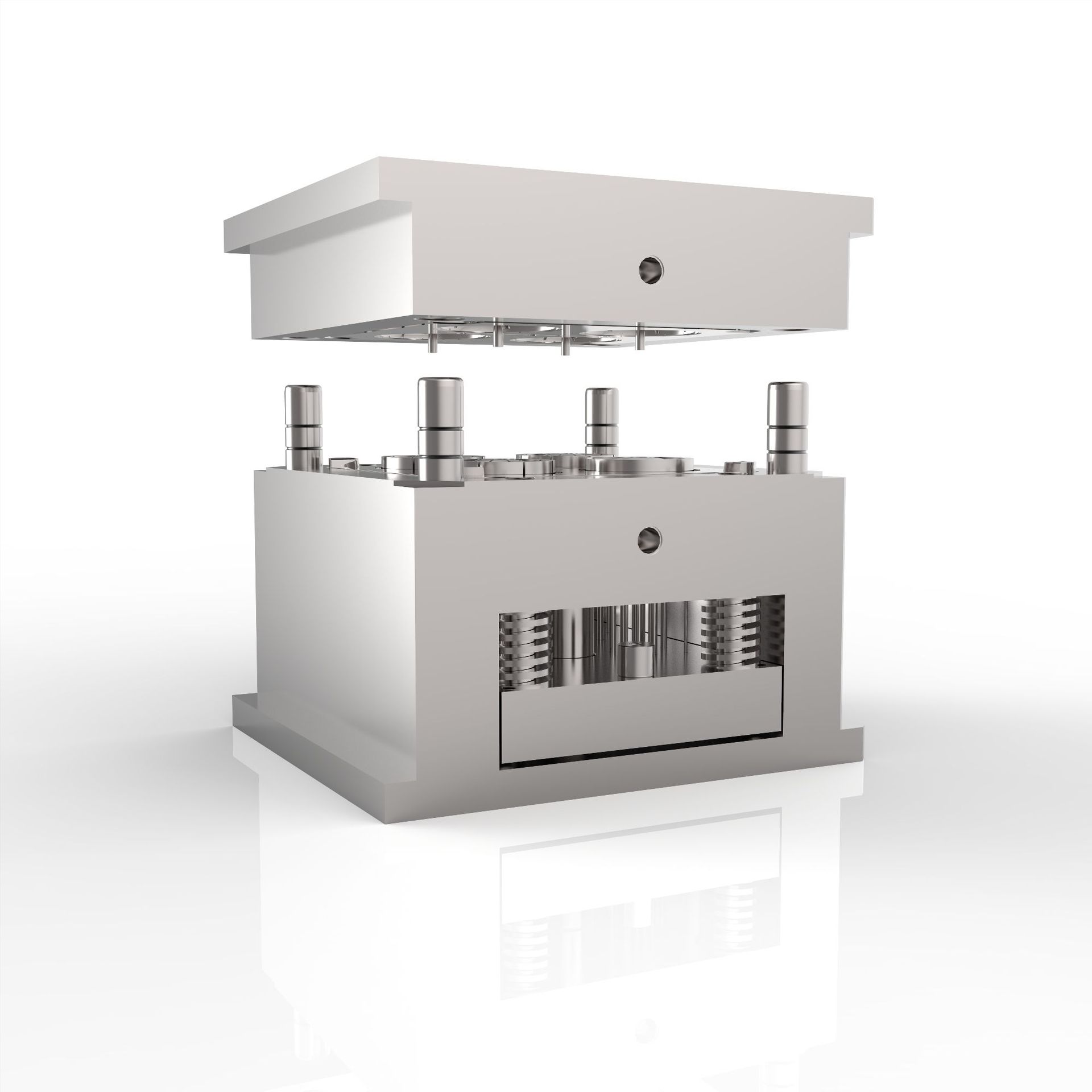

With 20+ years of experience in precision mold making, we deliver high-quality injection molds, die casting molds, and stamping dies to global customers.

Certified quality system

Industry experience

Worldwide shipping

Professional service

Comprehensive mold manufacturing solutions from rapid prototyping to high-volume production

Fast-track mold solutions for prototype and small production runs

High-volume production molds with maximum durability

Tailored mold designs for unique product requirements

High-precision molds for plastic parts with complex geometries

Professional molds for aluminum, zinc, and magnesium casting

Progressive and tandem dies for metal stamping

Advanced molds for multi-material or multi-color parts

Specialized molds for rubber and silicone products

Professional molds for plastic bottles and containers

Ultra-precision molds for medical and optical parts

Heavy-duty molds for automotive and large industrial parts

We ensure that every custom molded part has superior precision, durability, and a perfect fit.

Our systematic approach ensures high-quality mold manufacturing with precision design, strict quality control, and efficient delivery management.

Professional mold design with rigorous validation process

Comprehensive analysis of material properties, wall thickness, deformation, and gate location to prevent potential issues

Close collaboration with clients to understand product functionality, parting line requirements, and surface treatment specifications

Advanced mold flow analysis and structural simulation to ensure first-shot success in mass production

Systematic review process including initial structure discussion, designer self-inspection, and manufacturing team evaluation

Detailed design documentation and checklist system for quality assurance and future reference

We follow a systematic approach to ensure the highest quality molds delivered on time.

Analyze part design for moldability and optimize for manufacturing

Detailed mold design and engineering

Precision machining and assembly

Comprehensive inspection and testing

Mold trials and sample validation

Safe packaging and after-sales service

Find answers to frequently asked questions about our mold manufacturing services.

See what our global customers say about our mold making services and support.

Purchasing Manager, US Plastics Corp

Technical Director, German Auto Parts

CEO, Mexico Plastics